It's easy to get around having to lick envelopes by using a tube of envelope moistener on hand, but what if you want something different and you're not sure what's best for your needs? You'd think the answer would be simple, but we actually get lots of confused inquiries about different types of envelope seals. In this post, we’re taking you to envelope seal school and exploring the difference between gummed seal, self seal, and beyond.

Read on to learn more.

What is a Gummed Envelope?

We should address this particular question from the start because there’s often confusion between gummed envelopes and self seal envelopes.

First things first: they are NOT the same thing.

A gum seal envelope, usually called a “gummed” envelope, has a strip of water-soluble glue, or gum, on its flap. To seal the envelope, the gum must be moistened by being licked, dampened with an envelope moistener, or moistened by a mailing machine. After moistening, the flap can be pressed closed.

Gummed envelopes are the most traditional and widely sold because they are more cost-effective than self seal or flip and seal. Plainly put: they’re the least expensive!

Another advantage to gummed envelopes is that they’re the best choice for use in bulk mailing machines. Once the mail is inserted in the machine, the glue on the flap is automatically moistened and pressed closed, leaving the envelope and its contents ready for mailing.

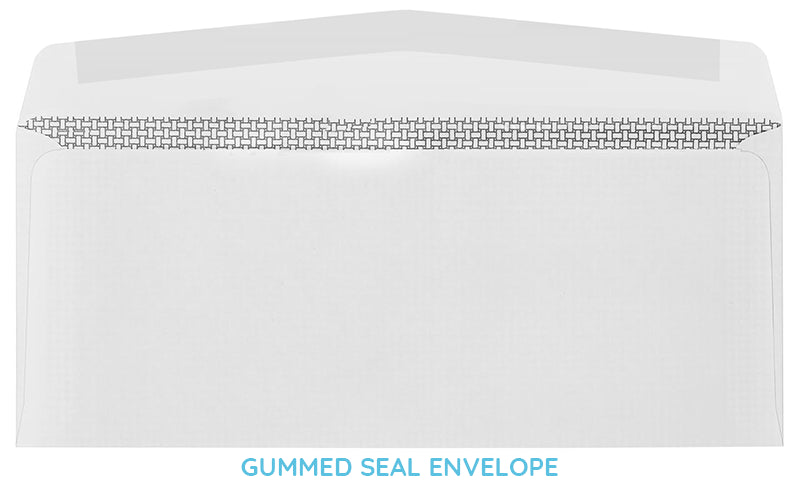

What is a Self Seal Envelope?

Self seal envelopes are known by lots of names: peel and seal, strip seal, peel and stick, zip seal, or super seal. They’re a popular and easy-to-use alternative to traditional envelopes because, unlike gummed seals, self seal envelopes don't need to be moistened. (No licking! No glue sticks! No yucky taste – hooray!)

Instead, self seal envelopes come with a sticky band of latex glue on the flap that is covered by a protective strip of paper or plastic. To seal these envelopes, simply peel off the protective strip to reveal the sticky strip, then fold the flap and press closed to form a bond.

One downside of self seal envelopes: they are not recommended for use in bulk mailing machines since they're not equipped to handle the protective strip, which poses a problem.

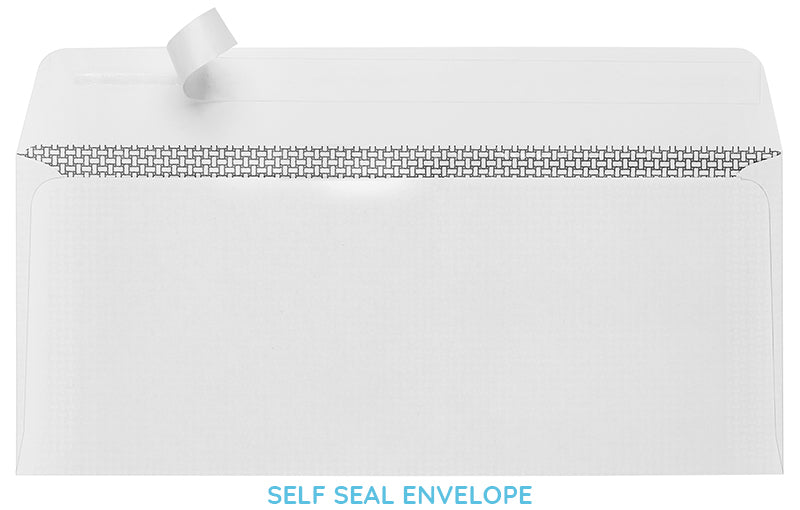

Are Flip and Seal Envelopes the Same Thing as Self Seal Envelopes?

Short answer: No.

Long answer: Unlike self seal envelopes which contain a single strip of adhesive on the flap, flip and seal envelopes have a strip of latex adhesive at two locations: one strip on the top flap and one strip on a folded bottom flap, which runs along the open edge of the envelope.

To close a flip and seal envelope, fold up the bottom flap to expose the adhesive strip. Then, fold down the top flap so that the two adhesive bands are pressed together. Ta-da! It’s flipped, sealed, and ready to send.

Flip and seal envelopes are unique in that they offer the convenience of self seal – no moisture needed – but with the added bonus of no extra waste, since there’s no protective strip to remove first.

A word of warning about storing flip and seal envelopes...

It’s recommended that flip and seal envelopes be used within 6-12 months of purchase due to the latex sealant on the flaps, which is a different material than the water-soluble gum used with other envelope seal types. Latex can lose its adhesive properties over time, especially when stored in humid conditions, so it typically has a shelf life of 12 months after its manufacturing date.

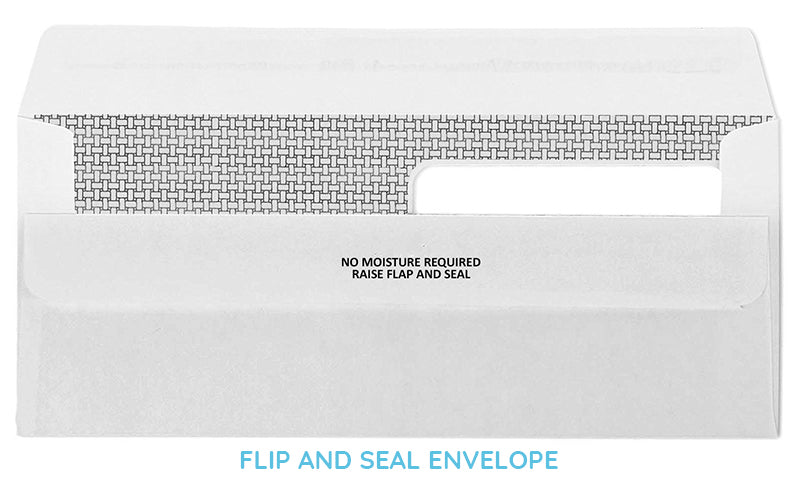

“But I thought self seal envelopes were the same as flip and seal.”

Well… yes and no, depending on who you buy your envelopes from. There can be a bit of confusion here, as some European office supply companies use the term “self seal” when referring to what most North American companies call “flip and seal.”

So to clarify once more, here at Blue Summit Supplies (an American company) we use the term “self seal” specifically when referencing envelopes that have a protective strip which must be peeled from its top flap in order to seal – AKA, “peel & seal.”

Conversely, a “flip and seal” envelope has TWO strips of adhesive on both edges of the envelope’s opening. When you flip up the bottom flap and fold down the top one, the adhesive bands are pressed together to form a seal.

Can the Adhesive on Envelope Seals Ruin My Printer?

That depends on the type of envelope and printer in question. First and foremost, we suggest reading instructions for your specific printer and/or printing a sample. But generally speaking, standard gummed envelopes do well in printers, as the water-soluble glue doesn’t typically clog printers.

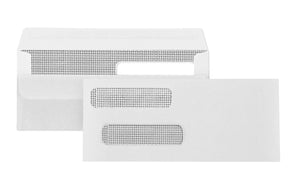

However, neither self seal nor flip and seal envelopes are recommended for use in printers. The protective strip on a self seal envelope may melt, and the latex glue on a flip and seal will almost certainly clog or damage your printer. Instead, we recommend using self seal or flip and seal envelopes that have double windows, which allow you to print your recipient and return addresses directly on the mail contents so they can be seen through the windows. Doing so means there’s no need for printing – just stamp and send.

Not all windowed envelopes are safe for use in laser printers, as the heat might warp or melt the window plastic. Take care to check when printing envelopes that they’re made to be safe for printing in your type of printer or copier to prevent machine damage or wasted envelopes.

Are There Only Three Types of Envelope Seals?

Of course not - that would be way too simple! Below are a few other seal types, some of which are commonly used and some less common.

Metal Clasp Gummed Closure

The metal clasp gummed envelope, also known as a gummed clasp closure, offers two methods for enclosing contents: Along with the common gummed seal, which requires moistening, it features a reusable metal clasp with prongs.

Because a metal clasp seal can be securely but impermanently sealed by foregoing the gummed seal, it is often seen used on larger booklet or catalog envelopes for an easy-to-use, secure method of hand-delivering interoffice communication or personal documents.

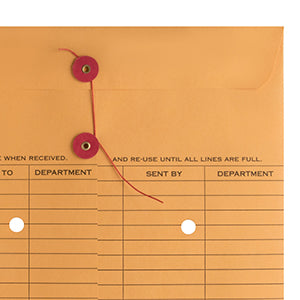

Button and String Fastener

This envelope seal sometimes is called a tie closure because of the way the string wraps, or ties, around buttons located on the two edges of the envelope opening.

Like the metal clasp gummed envelopes, string fasteners are seen most often on larger catalog-size envelopes and are another popular choice for interoffice communication and organization. The reusable tie closure holds the contents securely inside so they can be repeatedly passed between colleagues or departments without fear of losing important documents.

Button and string closures can be mailed via the U.S. Postal Service, but it will cost you. There is an additional hand-canceled charge on this type of seal because automated mailing machines cannot process envelopes with buttons or strings, so they must be processed manually.

Ungummed

Envelope seals with no gum at all come in handy for filing and transporting documents, especially contents that are handled/removed by lots of individuals. These seals are seen more often in the envelopes created for legal size documents and handled by lawyers or other law offices professionals.

Ungummed envelopes are also commonly used in formal stationery suites, such as wedding initiations, wherein the outer envelope is sealed and stamped for mailing, but the inner envelope is formally inscribed to the recipient. This inner envelope which contains the actual event invitation is traditionally left unsealed in order to present an elevated and pristine experience that, for courtesy’s sake, preserves the original envelope.

Of course, for obvious reasons, ungummed envelopes are not recommended for use in the U.S. mail system (unless for some reason you have no choice, in which you can manually seal the envelope yourself with a strong glue or tape).

Snaps or Hook-and-Loop Tape

Snaps or hook-and-loop tape (more widely known by the brand name Velcro) are closures you’d typically find on envelopes made of polypropylene – a form of plastic commonly referred to as “poly.” Alternative and unique, snap closures or hook-and-loop tape are also typically found on larger sized envelopes which allow for repeated reuse in offices or school settings.

As a fun added bonus, poly envelopes are often available in a rainbow of assorted colors. Bought as a set, they can be used as part of a simple color-coded organization system for important documents, or as a decorative and personalized yet functional option in classrooms or home offices.

Learn more about poly envelopes!

Wax Seals

Wax seals are seriously old school – dating all the way back to the 13th century! However, this technique is enjoying a resurgence in popularity on party initiations, wedding stationery, and even product packaging as a unique take on old world tradition.

Wax seals are formed by melting a wax stick over the closure so that the quick-hardening wax formula drips onto the paper and forms a hard seal that can be peeled or snapped open by the recipient. Used to secure mail well before the advent of modern postal security, wax seals would often be stamped with an insignia of the sender to prevent mail tampering. Today, you can still purchase decorative wax stamps, or even have a custom one made with your monogram or business logo.

This sealing method is fun but naturally more time consuming, and requires special considerations if you plan to actually mail it. For example, certain types of waxes are stronger and might hold up better in transit; still, it’s suggested that wax-sealed envelopes be enclosed in another envelope before mailing for security. And of course, the use of wax may cause your envelope to weigh more than normal, upping the postage price.

Signed, Sealed, Delivered...

...the choice is yours. But just to make sure you get exactly what you need and want, here a few tips to help make sure that when you order envelopes online, you're preventing any mix-ups.

- Always study the picture of the envelopes listing, specifically the seal type, before you purchase. We’ve found in our research that many names exist for the different kinds of envelope seals, and standard naming conventions vary from company-to-company and continent-to-continent. A picture really is worth a 1,000 words when it comes to making sure you’re buying what you think you’re buying.

- Know how you plan to use the envelopes before you buy. For example, if a bulk mailing machine will be used to stuff the envelopes, gummed envelopes are the best option – not self seal.

- Designate a clean, climate-controlled area for storing bulk orders of envelopes. Too much humidity or dust can ruin the gum on the seals.

- Gummed envelopes are the simplest of all, but do require moistening. They are nearly always the most cost effective.

We hope this helps clarify some of your questions about envelope seals. If not, please write Larry, our Chief Happiness Officer, at larry@bluesummitsupplies.com. She or one of our envelope experts will gladly help answer your questions and direct you to the best option for your needs!

For more informative articles about office supplies, subscribe to our email newsletter!

For more informative articles about office supplies, subscribe to our email newsletter!

Never fear, you won't begin receiving daily sales emails that belong in a spam folder. Instead, we promise a fun weekly roundup of our latest blog posts and great finds from across the web. And if you lose interest, it's always easy to unsubscribe with a single click.